Dec 16, 2020 | Announcement, Press Release

Packaging Utah Updated Brand Identity, Creates New Logo and Style Guide to Match Internet Domain Name to Better Serve the Utah Market Packaging Utah, a division of Traco Manufacturing, Inc., formerly Utah Packaging has updated their brand identity, changed their logo,...

Jul 7, 2020 | Announcement, Article

The Coronavirus By this point, most everyone has heard about the “novel coronavirus” and the accompanying disease it causes, Covid-19. The word, “novel” means “new,” so we are talking about a new type of coronavirus that we haven’t seen before. According to the CDC,...

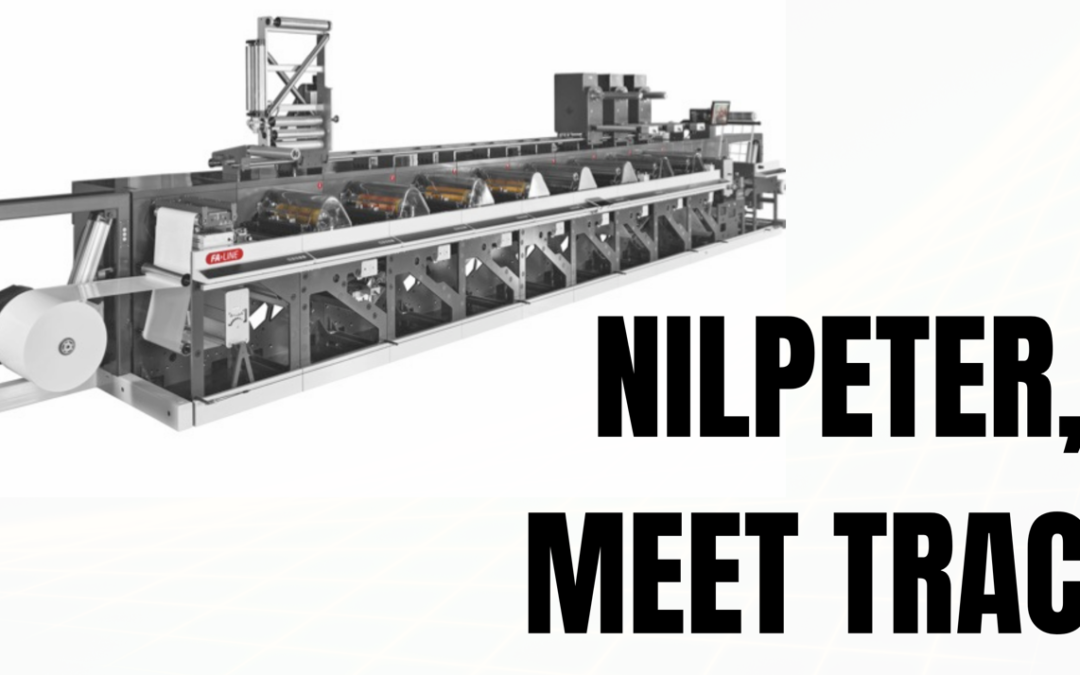

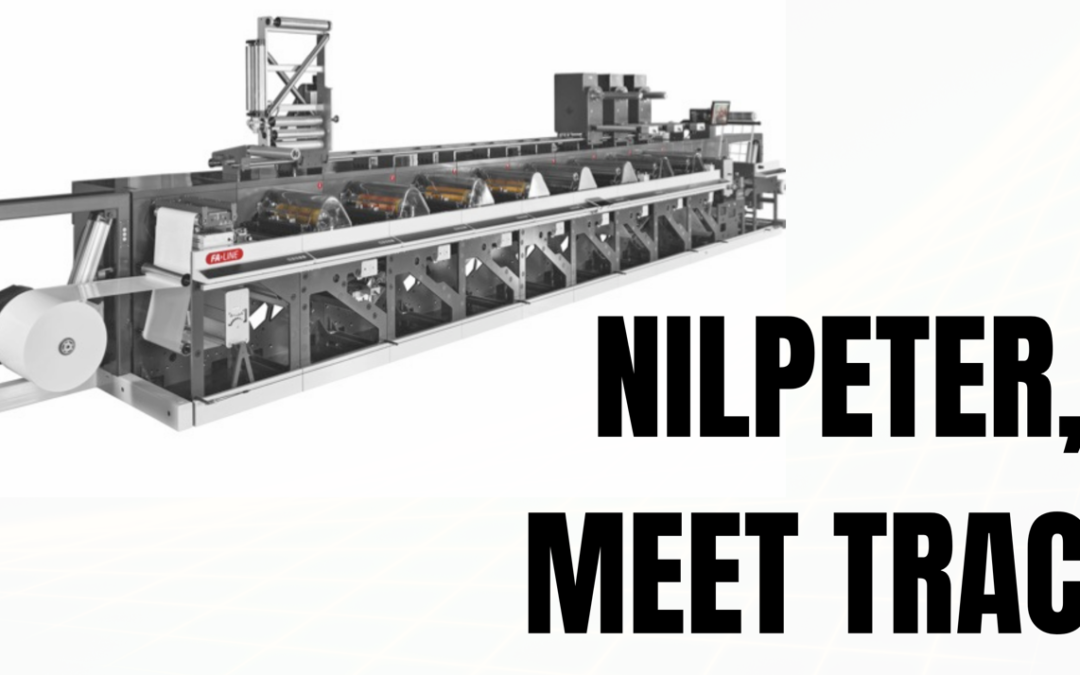

Feb 18, 2020 | Article, Packaging

There are several advantages of printing your pressure-sensitive labels digitally, but first, you might ask: “Why should I use pressure-sensitive labels for my project?” So, let’s define what a pressure-sensitive label is. What is a Label? A pressure-sensitive label...

Jan 3, 2020 | Article, Packaging

Overview Experts forecast that the market for legal cannabis will reach $57 billion by 2027, and many companies are becoming desperate to capitalize on it. Cannabidiol (CBD) products are becoming mainstream now that hemp-based CBD products are legal in all 50 states....

Jan 3, 2020 | Article, Packaging

Sustainability When we talk about sustainability with respect to plastics, the concept often meets skepticism. After all, most people think, “how can plastics be sustainable?” However, these assumptions relative to environmental impact are not accurate. Sustainability...